System Specifications

Free Trolley Load Centres

Using a typical free trolley set (leading and trailing trolley) with load bar, the minimum load bar accumulation centres are approximately 12-inches. Combination trolleys are available for small loads, accumulating on a minimum of 10-inch centres.

Pusher Dog Centres

Pusher dogs are solid cast steel with integral front pendant and loose rear pendant for attaching to the conveyor chain. Pusher dogs can be installed on a minimum of 12-inch centres.

Load Capacity

The maximum load that can be suspended from a 2-trolley load bar is 500 pounds.

Chain Pull

Chain pull is the force required to overcome the rolling resistance of the conveyor chain. The chain pull on a given system is proportional to the individual load weights, load centres, quantity of elevation changes, quantity of horizontal curves and overall environment that the system operates in. An average system chain pull will typically range between 2.5% and 5% of the sum of the moving load. Maximum chain pull for a single caterpillar drive is 750-pounds.

Contact Cirrus for chain pull calculations that relate to your system.

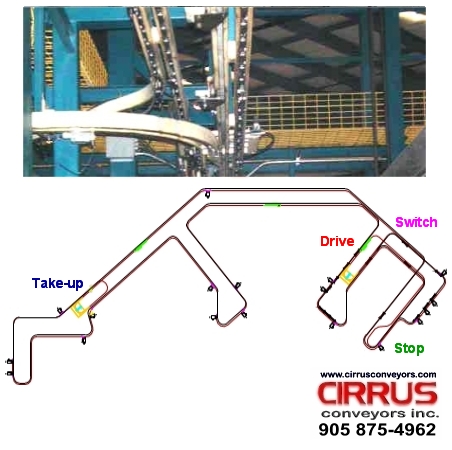

Typical System Components

Power Rail Components

See our FastTrack Conveyor System page for details on the power components of Cirrus FastTrack Power & Free.

Pusher Dogs

Pusher dogs provide the connection between the powered chain and the free rolling trolley / load bar assembly that carries product loads. Pusher dogs are constructed from solid steel with drive flipper, holdback flipper and chain pendants. The bolted assembly method allows for dog replacement without having to break the conveyor chain.

P&F Track

Straight track is comprised of two roll formed 3/16" wall enclosed tracks positioned side by side on 3-inch centres.

The overall track dimension, measured from the top of the parallel tracks to the underside of the lead trolley measures 7-5/16 inches. The overall width of the front carrier pusher arm is 12-inches. Track is finish painted beige and is available in 10-foot lengths.

Each system will contain at least one chain installation gate which also serves as an inspection port. This straight section of track is open at the top and is protected by a cover that slides on. The overall length of an inspection section is 24-inches.

Each system will also contain at least one free trolley installation gate. This gate allows open access to the free trolley track and measures 30-inches in length.

P&F Horizontal Track Curves

Horizontal curves are formed from two straight enclosed track sections and rolled to 24 and 27-inch centreline radius. Tracks are tied together on 3-inch centres with flame cut track yokes. Curves are shipped in segments of 45, 90 and 180-degrees.

P&F Vertical Track Curves

Vertical track curves are formed from two straight enclosed track sections and rolled to 48-inch centreline radius. Tracks are tied together on 3-inch centres with flame cut track yokes. In order to complete a change in elevation, two types of vertical curves are required. A lower vertical curve leads the chain from level to an incline and a top vertical curve takes the chain from an incline back to a horizontal position. Straight track situated between the vertical curves can be added to increase the overall incline or decline of the elevation change. Curves are shipped in segments of 30-degree, and 45-degrees.

P&F Accumulating Trolleys

Free trolleys, usually in combination with a load bar, carry product loads. Trolleys are fabricated with solid steel frames to which load bearings with guide wheels are attached.

Lead trolleys are positioned at the front of a load bar in the direction of travel. Pusher dogs, mounted on the conveyor chain, capture the trolley pusher arm. The holdback flipper dog located behind the drive flipper dog serves as a hold back to maintain pusher dog engagement when carriers are transitioning a track decline.

Trailing or rear trolleys are positioned at the rear of a load bar and share the load with lead trolleys. The configuration of trailing trolleys allow accumulation to take place when subsequent lead trolleys come in contact with the tail on trailing trolleys.

Combination trolleys which contain a pusher arm and de-latching tail are available for very small loads where accumulation required is as short as 10-inches.